A DTF (Direct to Fabric) printer is a specialized machine for printing on fabrics, offering quick turnaround times and eliminating costly set-ups. It works by directly applying ink using a digital print head, creating intricate gang sheets for various fabric types. Selection criteria include production volume, design complexity, and heat press settings. Entry-level models suit small operations, while advanced printers are needed for high-volume businesses. Consistent print quality requires considering material compatibility and optimal heat press settings. Choosing the right DTF printer aligns with production needs and ensures customer satisfaction.

Choosing the right DTF (Direct to Forme) printer is pivotal for optimizing production volumes. This article guides you through the process, offering insights into understanding DTF printers and their unique capabilities. We’ll explore key factors like print speed, resolution, material compatibility, and cost-per-print, all crucial when aligning your DTF printer selection with your specific production demands. By the end, you’ll be equipped to make an informed decision for enhanced efficiency.

- Understanding DTF Printers and Their Functionality

- Factors to Consider When Choosing a DTF Printer Based on Production Volume

- Matching the Right DTF Printer to Your Production Needs

Understanding DTF Printers and Their Functionality

A DTF (Direct to Fabric) printer is a specialized machine designed for printing on various fabrics, offering a direct and efficient method of fabric decoration. This technology has revolutionized the textile industry by enabling businesses to produce custom designs with precision and speed. Unlike traditional methods that require multiple steps and costly set-ups, DTF printers allow for quick turnaround times, making them ideal for both small orders and high-volume production.

The functionality of a DTF printer revolves around its ability to directly apply ink onto fabric using a digital print head. This process involves creating custom gang sheets (a term often used in printing) with intricate designs that can then be transferred onto numerous fabric types, from t-shirts and hoodies to flags and banners. For businesses dealing with dtf small orders or looking to create custom dtf gang sheets, these printers offer a cost-effective solution without compromising on quality or design complexity.

Factors to Consider When Choosing a DTF Printer Based on Production Volume

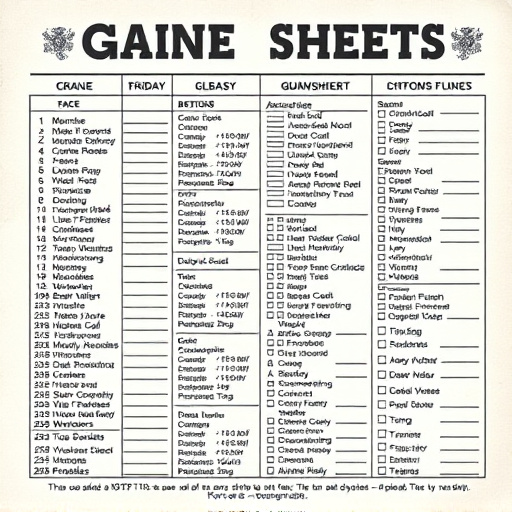

When selecting a DTF (Direct to Fabric) printer for your production needs, understanding and evaluating several factors is essential. One primary consideration is the anticipated production volume. This refers to the number of prints or transfers you expect to produce daily or weekly. For smaller-scale operations or startups, a less expensive, entry-level DTF printer might suffice, while larger businesses with higher printing demands may require more advanced models capable of handling increased throughput.

Additionally, think about the type and complexity of designs you’ll be printing. Simple, single-color UV DTF transfers for DTF custom apparel may have different requirements than intricate, multi-colored patterns. Ensure your chosen printer has the necessary features to accommodate your design needs, such as print resolution, color accuracy, and support for various file formats. Furthermore, consider the heat press settings and material compatibility to guarantee optimal printing results across diverse fabrics.

Matching the Right DTF Printer to Your Production Needs

When selecting a DTF (Direct to Fabric) printer, aligning your choice with production volume needs is paramount. Small-scale operations may opt for entry-level models offering lower cost and ease of use, ideal for experimenting and producing limited batches. Conversely, high-volume manufacturers require robust machines capable of handling extensive runs without compromising on dtf print quality.

Consider not only the expected output volume but also the specific requirements of your dtf application instructions. If you intend to create intricate designs with fine details, invest in a printer known for delivering high quality dtf transfers consistently. This ensures accuracy and precision, allowing you to meet customer expectations for detailed, vibrant prints on various fabric types.

When selecting a DTF Printer, aligning your choice with production volume needs is paramount. By carefully considering factors like print speed, capacity, and cost per print, you can ensure the right DTF Printer matches your output demands, enhancing efficiency and profitability in your printing operations.